作 zukuri Z.2.1 sharpening system

The shipping costs as well as the delivery time of available products will be communicated to you at checkout depending on your delivery location (country). See also the information on our "Shipping costs and delivery" page.

If "sold out" products are listed in the category "Announced", they will be available again in our shop within 3 to 6 weeks.

You can enquire about the availability of all other products marked "sold out" with us. Please feel free to contact us via the contact form or by phone.

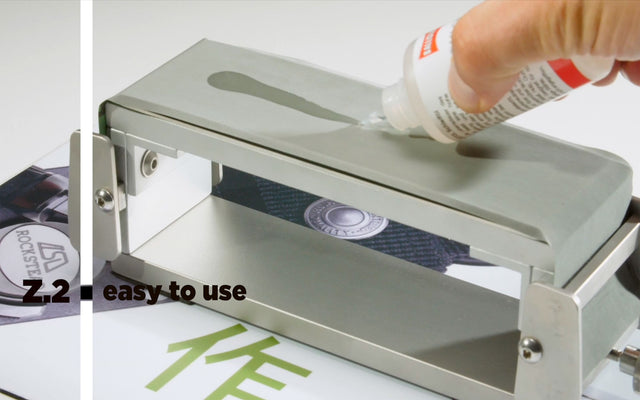

The zukuri Z.2.1 is a sharpening system that can be used to resharpen all common knives. It was designed to also enable the sharpening of convex blade shapes. The practical and extremely solid construction is modelled on a tool from the ROCKSTEAD Corporation and produced in cooperation with Schwarz Metallbau GmbH in Germany.

You can see how the Z.2.1 is used in this YouTube video:

YouTube video zukuri Z.2

As a further development of the Z.2, the Z.2.1 has an improved tensioning device that makes threading and tensioning the sandpaper much easier.

Technical data

1. Dimensions Z.2.1: maximum length 255mm, maximum width 80mm, height 67mm.

2. Size of the support surface: ( masterplate ): Length 200mm, width 60mm.

3. Weight: (without rubberised steel plate): 1.740 kg.

4. Surface: cast aluminium "Masterplate" - evenness: max. 0.13 mm, peak-to-valley height Ra = ≤ ~ 0.60 μm, food-safe according to DIN EN 601, corrosion-resistant.

5. Base plate: 1.4301 steel (V2A steel).

6. Tension rollers: 1.4301 steel (V2A steel).

7.Side parts and stabilising angle: aluminium.

8.Rubber components: resistant to ozone and weathering, good resistance to oil, chemicals, heat and water vapour.

Scope of delivery

1. zukuri tool Z.2.1 (with improved clamping device)

2. Rubberised steel plate.

3. 20x wet sandpaper with grit 1000.

4. 20x wet sandpaper with grit 2000.

5. BALISTOL grinding oil (65ml) - food safe.

Notes on sharpening with the Z.2.1

- In contrast to the use of whetstones, the Z.2.1 is only sharpened in one direction - see product video!

- The surface of the Z.2.1 consists of a high-quality cast aluminium plate ("Masterplate") with extremely low tolerances in terms of flatness and roughness. It allows the supplied wet-grinding paper to be fixed absolutely flat so that sharpening can be carried out evenly over the entire cutting edge.

- Due to the high weight of the Z.2.1 (1.7 kg) and the four rubber pads on the underside, a safe stand is guaranteed.

- The use of wet sandpaper ensures a high removal rate, which can be very well dosed depending on the pressure applied. The removal rate can also be influenced by using different grit sizes. For the final sharpness, a grit of 2000 is sufficient. For larger chipping that requires more material to be removed, wet sandpaper with grits of 800 or 1000 can be used.

- Tension rollers attached to the ends enable easy clamping of the wet sandpaper. They are rubberised on the contact surfaces so that only moderate pressure, which can be dosed by means of a knurled fixing screw, is sufficient to securely fix the wet sandpaper.

- When using the rubberised steel plate as an intermediate layer, a small amount of pressure is sufficient to maintain the convex ground edge. For sharpening blades with a flat grind or with a cutting bevel, this intermediate layer is not necessary and can simply be omitted.

- By using the grinding oil, the blade can be moved more evenly and accurately over the surface. It also gives the wet sandpaper a longer life and it clogs less quickly.

- The hand holding the knife only guides the movement of the blade and mainly determines the sharpening angle. The fingertips of the other hand control the pressure. It is recommended to check the removal after each sharpening movement (if necessary with a magnifying glass) to be able to correct movement and pressure in time.

- Optimal results are achieved when resharpening in only one direction on the wet-grinding paper by alternately guiding the knife in the right and left hand.

- If the blades to be sharpened are polished, the area of the cutting edge that has been resharpened can be reworked in a final step using a polishing block or other suitable means. However, this is not absolutely necessary to achieve the final sharpness.

Advantages of the Z.2.1

- Also suitable for convex blades.

- Permanently flat surface for more control over the sharpening angle used.

- Immediately ready for use, as no further preparation is required apart from fixing the wet-grinding paper and applying the grinding oil.

- Low follow-up costs due to inexpensive wet sandpaper.

- Time saving, as sandpaper allows high stock removal per sharpening movement.

- Flexible - one tool for a wide range of grit sizes.

- Space-saving due to compact design.

How to use the Z.2.1

You can see how to use the Z.2.1 in this YouTube video:

YouTube video zukuri Z.2

CONTACT

作 zukuri

Burnitzstrasse 58

60596 Frankfurt

Fon: +49 (0) 170 7788 264